Diesel injection systems have evolved dramatically over the past decade, becoming more precise and sophisticated. As a result, diagnosing faults in fuel injection pumps has become more challenging, which led to the development of advanced diagnostic tools powered by modern technology.

1- High-precision sensors for accurate measurements

Modern diagnostic devices rely on cutting-edge sensors capable of measuring:

Injection pressure with micro-level accuracy

Fuel delivery volume per pulse

Pump vibrations and noise patterns

Operating temperature

This level of precision was impossible with traditional manual methods.

2- Artificial Intelligence and data analytics

Many modern testers now integrate AI algorithms that can:

Identify the exact type of fault

Predict future pump failures

Compare pump performance with OEM specifications

Provide fast and reliable diagnostic results

This significantly reduces errors and improves maintenance quality.

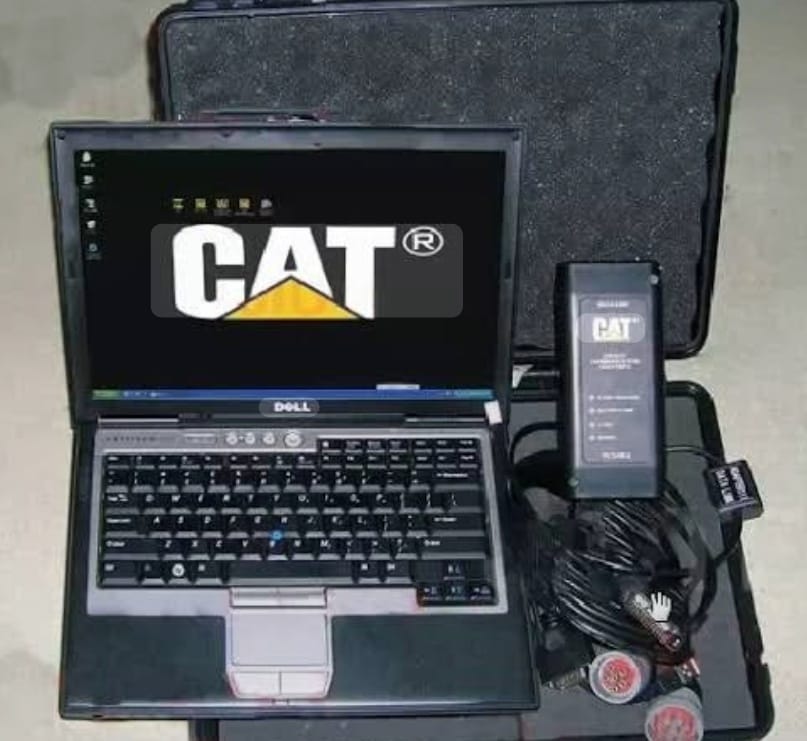

3- Connectivity: PC, Mobile, and Cloud

Most new diagnostic tools support:

USB

Bluetooth

Wi-Fi

This allows technicians to:

Display real-time pump data on a PC or tablet

Save and export diagnostic reports

Share results with customers or manufacturers

Update the device firmware online

4- Simulation Technology

Advanced devices can now simulate real engine conditions, including:

Low/High pressure scenarios

Different fuel viscosities

Extreme temperature conditions

This helps reveal hidden faults that do not appear in traditional bench tests.

5- Faster diagnostics and higher efficiency

Thanks to modern technology:

Diagnostic time is reduced by up to 60%

Repair accuracy is improved

Hidden or intermittent faults are easier to detect

Conclusion

Technology has completely transformed diesel pump diagnostics. It has made the process faster, more accurate, and more professional, ensuring better pump performance and longer engine life.